5 important factors worth considering when looking for the best cnc router

As technology advances, there is a high demand for efficient machinery like CNC routers. When shopping for a CNC router, it’s important to consider key factors that affect how well the machine works. Things like spindle power, cutting speed, software compatibility, and build quality all play a role in finding the best CNC router for your needs. Taking a close look at these factors is not just important, but it’s a smart investment in being more productive and getting great results with precision cutting and carving.

See our guide to the best cnc router.

Type of material to be machined

When thinking about buying a CNC router, it’s important to think about the type of material you’ll be working with. The material you choose will affect how well the machine works and the quality of the final product. You need to pick a CNC router that’s good for the specific material you’ll be using to make sure it performs well. Knowing about different materials will help you make a smart choice when buying a CNC router, which will help you work better and get better results.

Matching the material to the right CNC router not only makes the machining process better but also makes the machine last longer. Choosing a machine that fits the materials you use a lot will reduce how much the router wears out, which means less money spent on fixing it and less time with the machine out of order. By thinking about the materials you’re using, you can make your CNC router work better and last longer, making it a valuable tool for your work.

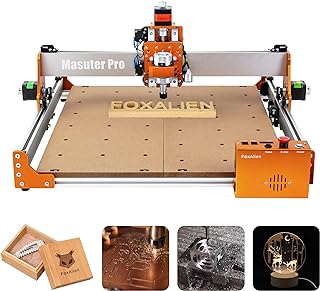

Size of the work area

When you’re looking to buy a CNC router, don’t forget to consider the size of the work area. A bigger work area lets you work on different project sizes and materials, giving you more options and room to be creative. It also saves time and helps you work more efficiently by reducing the need for multiple setups.

On the other hand, choosing a CNC router with a smaller work area can limit your creativity and make it harder to grow your business. You might have to compromise on the size and detail of your projects. While a compact machine can work for simple projects, a larger work area gives you flexibility and prepares you for future growth.

In the end, the size of the work area isn’t just about measurements; it’s about letting you be more creative and make the most of your CNC router’s potential.

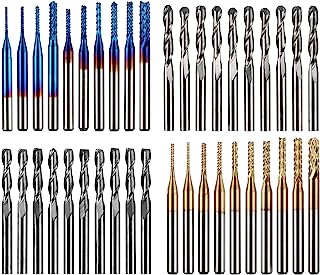

Spindle power and speed

When you buy a CNC router, it’s important to think about how strong and fast the spindle is. The spindle is key in deciding how well and accurately the machine cuts. A stronger spindle can easily cut tough materials, while a faster spindle speeds up the cutting process. It’s crucial to find a good balance between power and speed based on the materials you’re using and the complexity of your designs.

Having a powerful spindle with the right speed settings can greatly improve how well your CNC router works. It helps you make precise cuts and handle a variety of projects. By carefully considering your needs and understanding different spindle options, you can choose the best one for your production goals and budget. Getting the right spindle setup can make a big difference in how efficient you are and the quality of your woodworking or machining projects.

Software compatibility

When you’re thinking about buying a CNC router, it’s important to consider if the software you want to use with it is compatible. The software you use with a CNC router can affect how well it works. Make sure the software you pick works with the specific model of CNC router you’re getting. If the software and hardware don’t work well together, it can cause problems and be expensive to fix.

Choosing software that works well with your CNC router can make your work easier, help you produce things faster, and let you use all the features of the machine. It’s a good idea to think about software compatibility when deciding which CNC router to buy. By choosing software that fits your CNC router’s abilities, you can make the most of the machine and increase your productivity. Whether you care about having an easy-to-use interface, advanced design features, or specific programming tools, it’s important to make sure your software matches your CNC router model.

Technology is always changing, so it’s important to keep up with software updates and compatibility requirements to protect your investment in a CNC router for the long haul.

Budget

Investing in a CNC router is an important decision that can greatly impact your production and efficiency. While it may be tempting to choose the cheapest option, quality usually comes with a higher price. Setting a budget that matches your needs and goals is an important strategic investment for your business.

Think of your budget as an investment in precision, reliability, and performance. Choosing a CNC router that fits your budget and also offers accuracy and durability will improve your output quality and productivity. Spending a reasonable amount on your CNC router can give you access to more features, better technical support, and help future-proof your operations against technological changes.

By seeing your budget as a way to maximize the value of your CNC router investment, you can ensure that each dollar you spend contributes to the growth and success of your business in the long term.

Conclusion

In conclusion, a CNC router is a game-changer in manufacturing. It is incredibly efficient and accurate, surpassing traditional methods. Whether it’s intricate woodwork or complex metal fabrication, the CNC router showcases technological advancement and endless possibilities. Using this tool not only makes production easier, but also fosters creativity and pushes industries towards a future of precision and productivity working hand in hand. Want more info on conditioner, check the best conditioner.