5 important factors worth considering when looking for the best cnc router bits

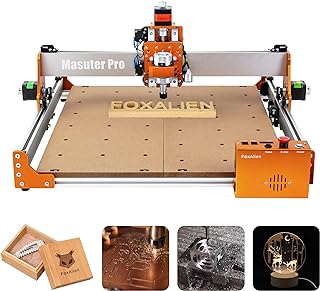

When exploring CNC router bits, it is important to prioritize precision, durability, and effectiveness. With various options available like spiral bits and straight bits, as well as different materials like carbide and high-speed steel, one must find a balance between quality, cost, and how they will be used. Choosing the right CNC router bit goes beyond just buying a tool; it is about enhancing craftsmanship and efficiency in woodworking, engraving, and cutting. By understanding the key factors that impact your choice, you can unlock new levels of creativity and productivity.

See our guide to the best cnc router bits.

Material of the router bit

The type of material you choose for your CNC router bits is important because it affects how well they work for cutting or carving. Carbide is a popular choice because it is durable and can keep its sharp edge when cutting tough materials. Even though carbide bits may cost a little more at first, they are a good investment because they last a long time and perform well.

On the other hand, high-speed steel (HSS) router bits are a more affordable option that still offer good quality. HSS bits can work with many different materials and are a good choice for beginners or anyone looking for a cost-effective solution. While they may not be as durable as carbide bits, HSS bits can still produce good results for lighter cutting tasks.

Deciding between carbide and HSS router bits depends on what you need and how much you can spend. Whether you choose carbide for top performance or HSS for affordability, picking the right material for your router bits is an important step in getting the best results for your CNC projects.

Type of cutting edge (e.g. straight, spiral, compression)

Choosing the right CNC router bits can greatly impact the quality of your work. There are different types of cutting edges, each with its own advantages. Straight cutting edges work well on various materials, providing clean cuts. Spiral cutting edges reduce chipping and splintering, resulting in a smooth finish with increased speed. Compression cutting edges combine upward and downward motions, making them ideal for laminated materials and delicate veneers. Understanding these cutting edges leads to more precise machining results and improves craftsmanship.

In the world of CNC machining, selecting the right cutting edge is a mix of practicality and creativity. By choosing the best cutting edge, you enhance the performance of your CNC router and elevate the beauty of your creations. Whether you value efficiency, precision, or versatility, each type of cutting edge offers unique possibilities to explore. Using straight, spiral, or compression cutting edges allows craftsmen to push boundaries, experiment with new materials, and achieve high levels of finesse in their projects. Essentially, the cutting edge you choose shapes the story of your craft, influencing your creativity and paving the way for innovative design projects.

Shank size

When buying CNC router bits, the size of the shank is important but often overlooked. While many people focus on the cutting edges and materials of the bit, the shank size also plays a big role in how well the tool performs. Choosing a larger shank size makes the bit more stable and precise, leading to smoother cuts with less vibration. Even though bits with larger shanks may cost a bit more, they last longer and perform better in the long run.

Some people argue that smaller shank sizes are better because they can fit into more collets and routers, making them more versatile and cost-effective. However, using smaller shank sizes can result in less accurate cuts and make the tool less sturdy. In CNC routing, precision is crucial, and smaller shank sizes may not always deliver the level of accuracy needed for intricate projects. By prioritizing larger shank sizes when picking router bits, users can improve their work, achieve cleaner cuts, and prolong the life of their tools. In the end, the shank size may seem like a small detail, but it has a big impact on the overall performance and quality of CNC routing.

Flute number and configuration

When you’re buying CNC router bits, it’s important to think about how many flutes and what kind of configuration you need. Flutes play a big role in how well the bit can get rid of chips, which affects how well and how fast it cuts. Bits with more flutes, like four or more, can give a smoother finish on softer materials. On the other hand, bits with fewer flutes, like two or three, are better for tough materials because they can clear away chips better. The flute configuration, whether it’s upcut, downcut, or compression, also makes a big difference in how the finished product looks and how well the material is removed. Upcut bits push chips up to avoid melting or burning, while downcut bits push chips down for a clean surface. Compression bits combine the benefits of both, making them good for many different cutting jobs. To pick the right flute number and configuration, you need to think carefully about what your project needs and what kind of material you’re working with. This will help you work more efficiently and accurately.

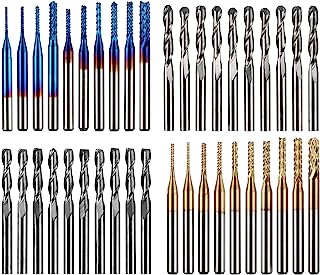

Coating or surface treatment

Choosing between coated or treated surfaces for CNC router bits can have a big impact on how well they work and how long they last. I believe it’s important to invest in bits with good coatings or treatments to get the best results and make the tools last longer. These special coatings not only make the bits stronger, but they also reduce friction when cutting, resulting in smoother finishes and more efficient work. Even though coated bits might cost more initially, the benefits of them lasting longer and cutting better in the long run make them worth it for any woodworking or machining project.

Additionally, picking CNC router bits with advanced coatings or treatments can give a competitive advantage by allowing users to work with more materials and create finer details in their projects. Whether it’s a diamond-like carbon (DLC) coating for better wear resistance or a special ceramic coating for cooling, the right treatment can make a big difference in how precise and high-quality the finished project is. By focusing on the quality and technology of coatings on CNC router bits, users can improve their craftsmanship and make the most of their machining abilities.

Conclusion

CNC router bits are like hidden gems in woodworking and manufacturing. They quietly play a crucial role in bringing ideas to life with precision and creativity. These small but powerful tools are essential for pushing the boundaries and transforming raw materials into beautiful works of art. Their versatility and precision empower artisans and manufacturers to express their creativity and drive industries forward. Overall, CNC router bits are vital in the process of bringing ideas to reality and making a lasting impact. Want more info on cervical traction device, check the best cervical traction device.