5 important factors worth considering when looking for the best cnc router machine

Choosing a CNC router machine is an important decision for both hobbyists and professionals. To make the right choice, it’s crucial to focus on key factors. These include the machine’s size, power, precision, and compatibility with different materials. Additionally, factors such as software compatibility, maintenance needs, and customer support are important to consider when selecting a CNC router machine. By carefully examining these aspects, you can ensure that you make a wise investment that will enhance your craftsmanship and innovation.

See our guide to the best cnc router machine.

Machine accuracy and precision

When looking to buy a CNC router machine, it’s important to consider how accurate and precise it is. Accuracy and precision play a big role in how well the machine works. Accuracy means how well the machine can make designs without making mistakes. Precision is about how well the machine can do tasks with great detail.

It’s crucial for buyers to think about both accuracy and precision to make sure the machine can meet different project needs. Getting a CNC router machine that is accurate and precise can help improve productivity and make better products. Machines that can make precise cuts and measurements allow manufacturers and craftsmen to create intricate designs perfectly.

Having a CNC router machine that is both accurate and precise lets users be more creative and make higher-quality products. In a market where precision and quality are important, having a machine that focuses on accuracy can help make work smoother and improve the final results.

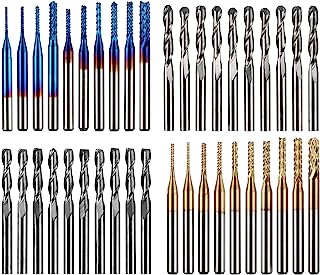

Spindle power and speed

When you start using CNC router machines, it’s important to understand how important spindle power and speed are for getting the precision and efficiency you want. The spindle is like the heart of these machines because it controls how detailed and fast your projects turn out. Choosing a high spindle power lets you work with lots of different materials easily, while faster speed means you can make things more quickly and be more productive. Having both power and speed is key to making really great products in the world of CNC.

Knowing how spindle power and speed work together is like unlocking the full potential of your CNC router machine. It’s a balance that not only affects how good your projects are, but also how easy it is to use the machine overall. Understanding this balance helps you do more with your designs and solve tricky machining problems. Power and speed aren’t just technical things with CNC routers; they’re a mix of creativity and engineering that helps you come up with new ideas in the world of digital fabrication.

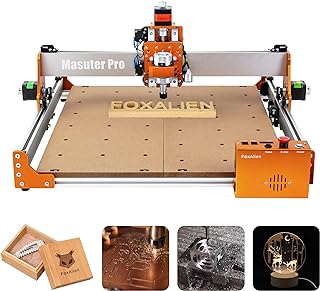

Work area size and capacity

When purchasing a CNC router machine, it’s important to consider the size of the work area. The work area affects the types of projects you can do and how big they can be. While a larger work area may seem like a good idea for future projects and versatility, it’s important to find a balance between size and practicality. Think about the size of your typical projects and the materials you use to make sure you get a machine that meets your current needs and future goals.

Having a bigger work area allows for more detailed designs and larger production runs, which can improve your efficiency. On the other hand, a smaller work area may require you to move materials more often, causing downtime and logistical issues. Make sure to carefully consider the space you have available and the types of projects you do before deciding on the right work area size for your CNC router machine. Precision and accuracy are crucial in CNC machining, so choosing the right work area size can have a big impact on the quality of your work and the success of your projects.

Control system and software compatibility

When it comes to CNC router machines, it’s really important to consider how the control system and software work together. This connection is what makes the machine run smoothly and accurately. If you don’t think about this before buying a CNC router, you could run into a lot of problems later on. It’s like getting a fancy car and putting bad gas in it – it just won’t work right.

Making sure the control system and software can work well together might seem overwhelming, but it’s essential. Choosing a CNC router that can work with different software options will help you protect your investment and give you more ways to be creative and customize your projects. When the control system, software, and hardware all work well together, you can get the most out of your CNC router, making your projects better and more efficient. In the world of CNC technology, it’s important to stay updated and make sure everything works together perfectly to get the best results from your CNC router.

Price and overall value proposition

When you’re thinking about buying a CNC router machine, the price is usually the most important factor. It’s normal to want a good deal, but just looking at the initial cost might not be the best approach. Instead, you should consider the overall value of the machine. Even though a cheaper machine might seem like a great deal at first, it’s important to think about things like how long it will last, how well it performs, and how much it will cost to maintain in the long run. Spending a little more on a higher-quality CNC router machine can pay off in the future by giving you reliability, accuracy, and efficiency that can really boost your productivity and profits. Remember, quality is usually not cheap, but the benefits it provides can outweigh the initial price tag.

In the world of CNC router machines, the saying “you get what you pay for” is often true. It’s important to find a good balance between price and quality to make a wise investment without sacrificing performance. Take the time to look at the features and capabilities of the machine and see how they match up with your needs and production requirements. Keep in mind that a more expensive CNC router machine may come with advanced technology, better construction, and great customer support, all of which add to its overall value. While money is a concern, don’t just focus on the price – think about the long-term advantages that a quality CNC router machine can offer to your business.

Conclusion

In today’s digital world, the CNC router machine is a game-changer that blends traditional craftsmanship with cutting-edge technology. This machine can turn complex designs into real-life objects with amazing accuracy, showcasing the endless possibilities of this advanced technology. As CNC router machines become more accessible and user-friendly, they are not only expanding creative boundaries but also allowing people to bring their ideas to life faster and more precisely. The world of CNC routing is a place where innovation, creativity, and precision come together, creating a future where even the most challenging projects can be accomplished with ease. Want more info on exbox one s, check the best exbox one s.